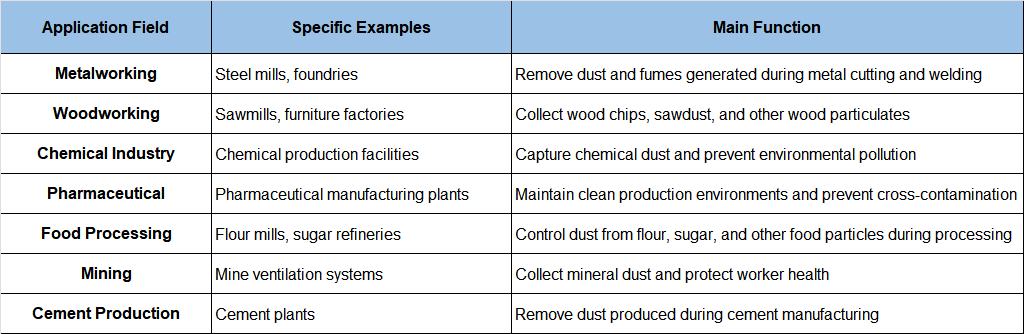

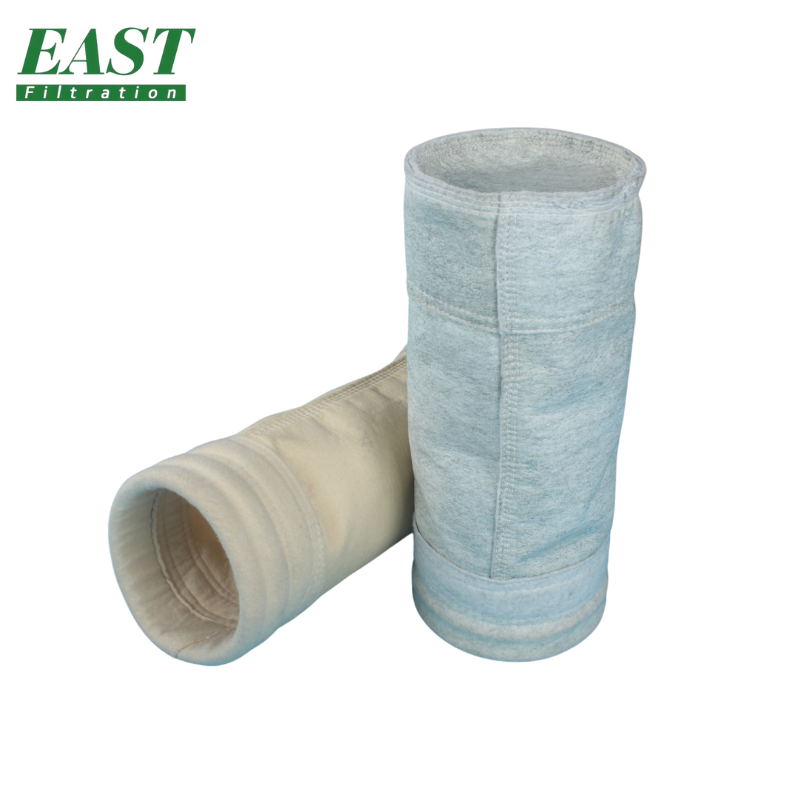

Dust collector bag

Material: Dust collection bags are typically made from durable synthetic fibers or blended fibers that offer good filtration performance and resistance to chemical corrosion.

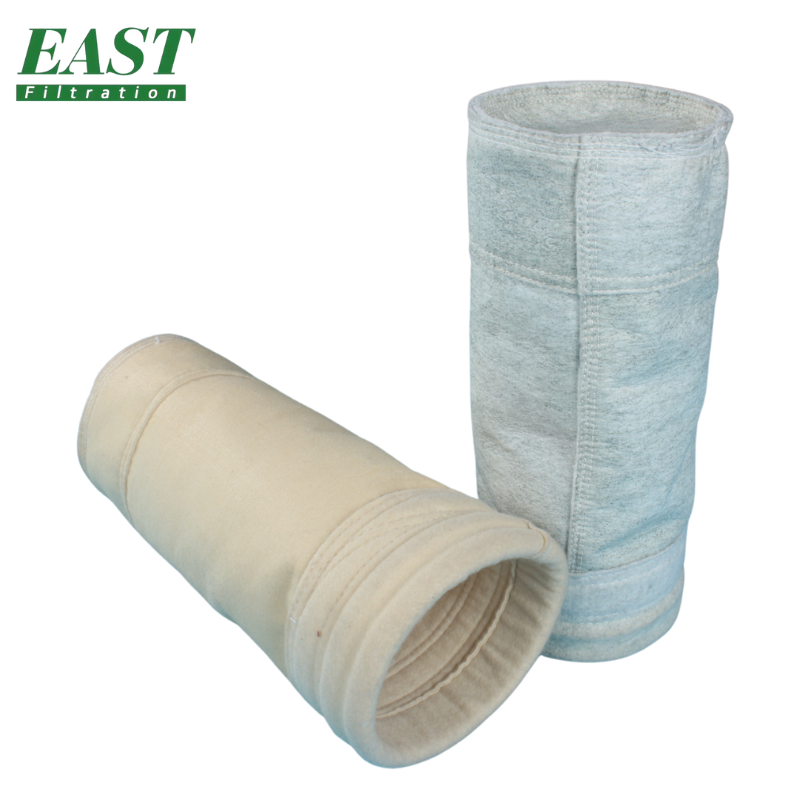

Design: Designed as bag-shaped units that can be installed on the filtration units of dust collection systems. Some bags come with anti-static features to accommodate the collection of combustible dust.

Size and Specifications: Available in various sizes and specifications to suit different airflow rates and types of dust, depending on the application.

Filtration Efficiency: Capable of effectively capturing dust particles in the air. The filtration efficiency varies based on the material used and the design details, with some high-performance bags achieving very high filtration rates.

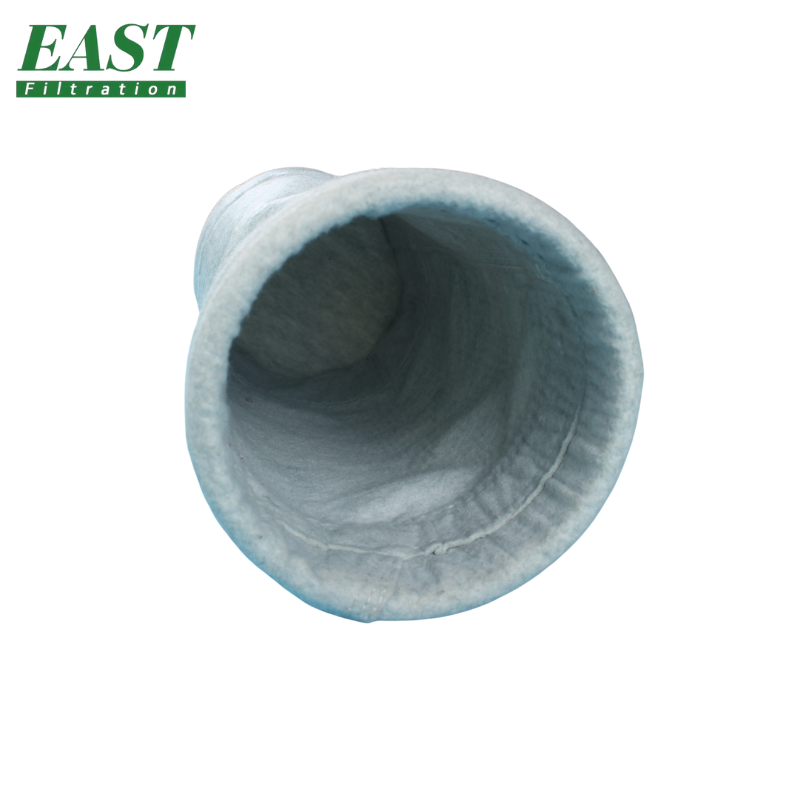

Application Range: Widely used in industries such as metalworking, woodworking, chemical processing, and pharmaceuticals for the removal of dust and fumes generated during production processes.

Maintenance and Replacement: Regular inspection is required, and bags should be replaced according to wear and tear to ensure continuous efficient operation of the system.

Dust collection bags play a crucial role in industrial production, helping factories meet environmental standards, protecting employee health, and maintaining the proper functioning of equipment.

Technical Parameter

Use to